Distributor Build Up

The factory method to lubricate the distributor shaft (from what I understand) was a prelubed piece of felt under a washer above the bushing. Here I'm trying to give access to the bushing for a shot of your favorite lube.

To drill the hole, I flattened a spot out on the lip to give the drill bit a flat spot to dig into. Then from the outside of the housing I drilled a small hole, big enough for a typical spray tube nozzle.

After drilling the hole I reinstalled the felt and peened the washer back in place. I don't think the felt washer is really needed anymore and most of the time they fall apart on diss-assembly anyway.

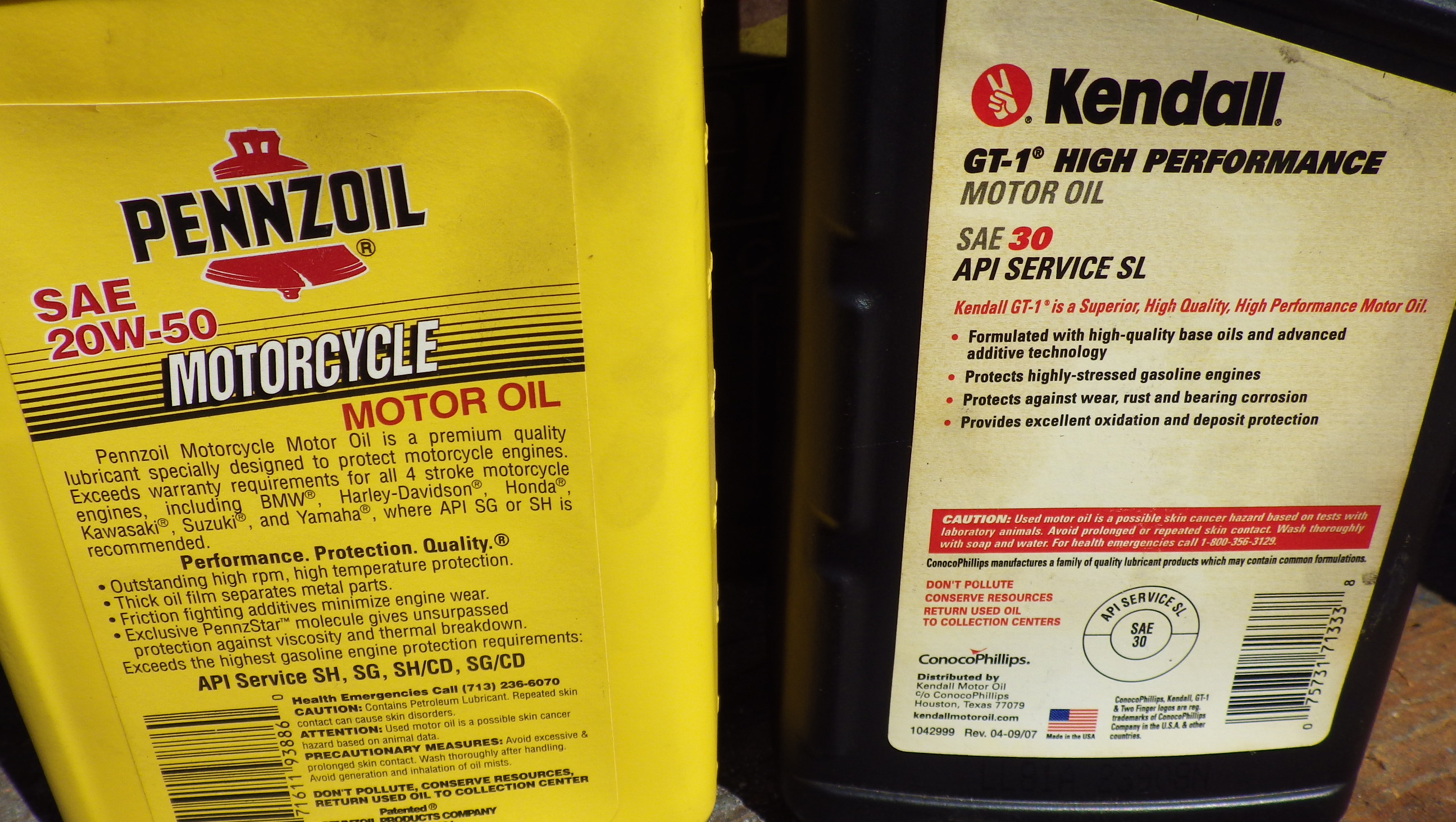

Another way to lube the bushing is a grease fitting or zerk, but I thought a little hole would be less noticeable than a grease fitting. These bushings are probably supposed to be oiled for the life of the bushing, something like Oilite (oil impregnated bronze) brand is designed to do. I've just seen too much wear on bushings and scratches on the shaft to believe any of that, so adding a little lube every few thousand miles via a little drilled hole probably won't hurt.

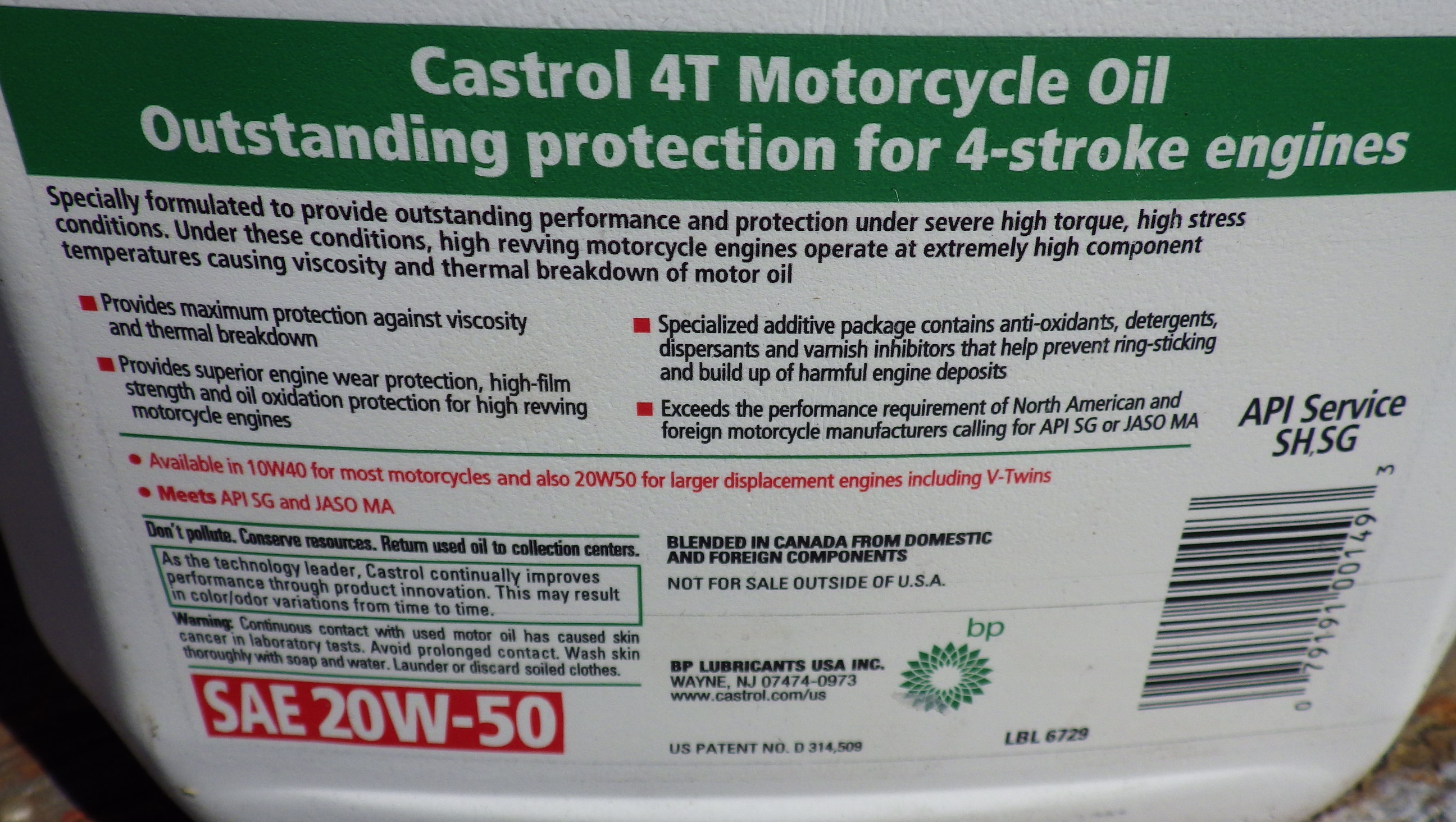

This is only a couple ways to renew your bushings by using common VW starter bushings. One is thin walled and one is thick.The original bushing is shown with the reamer. Part numbers for the bushings are visible in this picture. 113-301-156 is for converting a 12 volt to 6 volt Trans/Starter and it has an ID much smaller than Fiat's .490 distributor shaft. The outer Diameter seems identical to Fiats OD on the factory bushing. Both are usable, just depends on how you want to approach it.

Here is the thin bushing pressed into the reamed-out original bushing. The thin bushing has the best inner diameter fit on the shaft for any of the 3 distributors Fiat 850's came with. The OD is what is not ideal and the quickest way I had to make it work was to ream out the original worn bushing.

This approach did remove all the slop/play the shaft had and now the ignition timing doesn't seem to jump around like it used to.

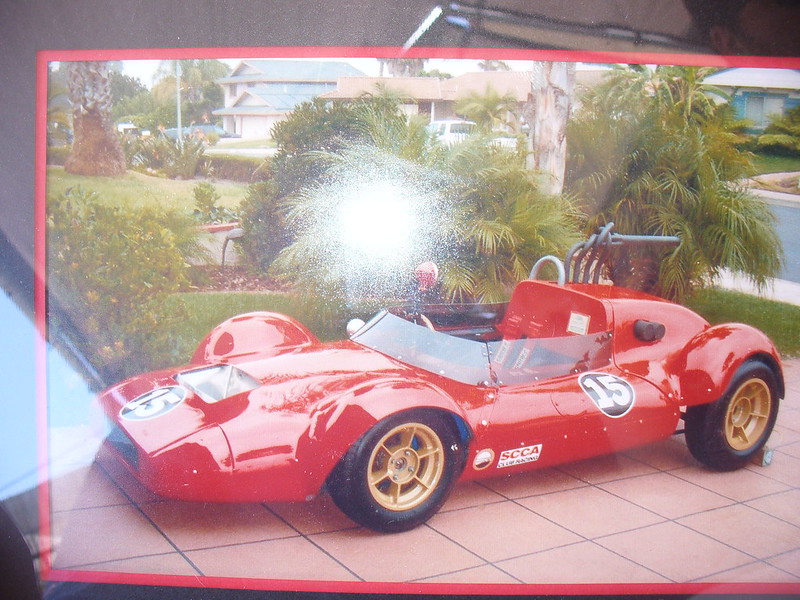

These idea's started with Mr John Griffith of Le Grand fame. Here he is uncovering the one-off chassis he still owns.

He dug-up an old VW starter bushing out of his inventory in an attempt to help out on this distributor problem.

This is a picture-of-a-Picture, but it's the best I can do for now. It's a Le Grand Race car which often ran 600/850 power.

Here is a different version with the famous Le Grand wheels.

The thick bushing I didn't use, but it does have the same OD as the bottom of a late Marelli where the ID would have to be drilled or reamed out to something

close to 1/2" or to be exact .495. I've seen the use of a bushing in the bottom of the distributor housing to give extra support to a top worn-out bushing. Some rebuilders may have used this practice as I can't tell if the factory ever used two bushings in one housing.

The shaft on all three distributors Fiat 850's came with (French and both Italian) is .490". This odd size ruins the possibility of using any .500" bearings as they fit too loose for everything I tried. 12mm is too tight and 12.5 is too hard to find. Custom machining seems to be the only way to achieve renewing these distributors. At least the early Marelli with the advance on top gives you access to the bushing for lubrication. If your lucky, maybe the previous owner of the engine happened to lube that hidden bushing. :sad:

Since this FIRST attempt at re-bushing the distributor I've found a 12mm ID needle roller bearing and Oilite bronze bushing that might work out better.

They are all on order now from various vendors, so when they do arrive, I will share all the information right here. The VW starter bushing approach was just a quick way to start experimenting with this trouble spot for 850's.